Caracol welcomes 2022 with great news: SAI Global has certified Caracol and its Robotic Large Scale Additive Manufacturing process for the production of aerospace parts, with the globally recognized AS/EN 9100:2018 standard.

Following several years of joint research with aerospace OEMs and Tier 1 companies, Caracol had the opportunity of focusing its work on testing new materials, printing process parameters, and different aspects of its Robotic LSAM process. The effort has been coronated with the achievement of this accreditation, which is the most ambitious manufacturing certification in the aerospace sector and has allowed Caracol to become part of the IAQG OASIS community of registered companies.

Therefore Caracol becomes the first Italian company to obtain this certification to produce Aerospace parts with large-scale additive manufacturing processes. The evaluation conducted analyzed, mapped, and developed processes to ensure that the company could guarantee the necessary industry standards.

Thanks to the system qualification and materials characterization process, Caracol has been able to guarantee parts reliability, repeatability, and quality standards in line with AS/EN 9100:2018 strict requirements.

A significant milestone for LSAM technologies.

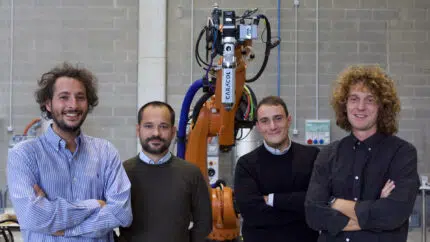

“This achievement is a key milestone in our proprietary Robotic Large Scale AM system development, we’ve culminated all the research efforts carried out with our aerospace partners over the past few years,” says Francesco De Stefano, CEO and Co-founder. “With our RO-LSAM process Aerospace OEMs and Tier 1s will be able to produce certified and qualified parts, finally being able to push LSAM into the production of large scale tooling and finished parts.”

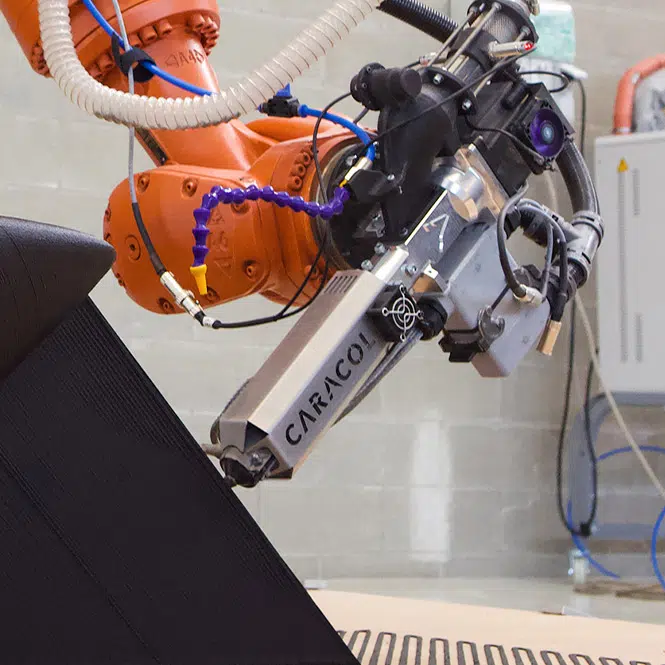

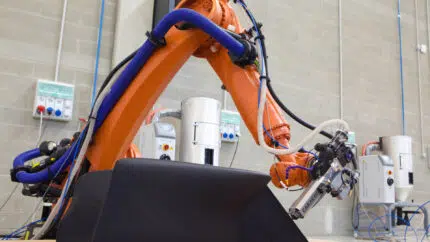

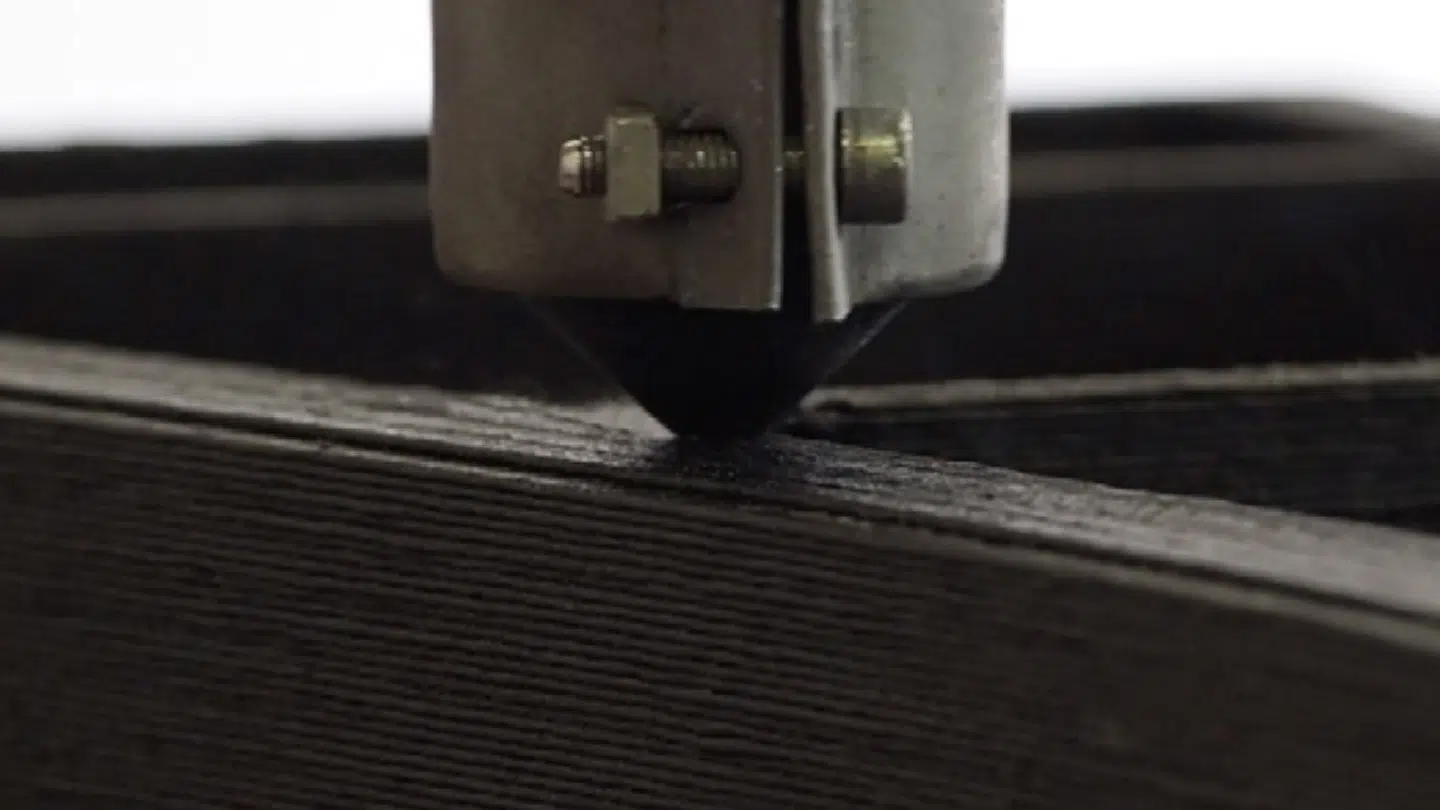

Caracol has been working towards this milestone for several years. Bringing together patented extrusion head, feeding system and printing head, with a proprietary software platform, and the use of robotic arms, the company has been capable of manufacturing components with no limits in scale with advanced composite materials. Moreover, this technology provides companies with a solution that saves costs, reduces production lead time, and provides environmental savings (e.g., limiting production waste to a minimum, being able to use recycled material and waste).

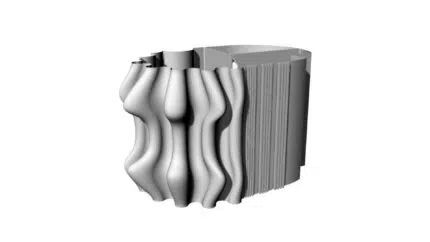

After manufacturing several significant aerospace components last year – such as the large-scale tooling for aircraft manufacturing and propellant tanks for satellite deployers – and going through different aerospace OEMs product qualification processes, Caracol’s work has been endorsed by the achievement of this certification. With the AS/EN 9100:2018 the company is currently scaling up the production of various components for aircraft, launcher, and satellite manufacturers.