The Evolution of Caracol: the commercial launch of Heron AM, a new home, and a renewed brand identity.

Caracol announces a new stage in its life: its Evolution.

Caracol’s journey of relentless innovation began over seven years ago, when our four co-founders began researching the potential of Large-Format Additive Manufacturing. From day one they began looking into how they could overcome the limits of existing AM technologies, to better serve the needs of clients in the most advanced industrial sectors.

This journey led Caracol to grow from start up to scale up and today we are commemorating this milestone with the launch of a new identity and a new direction. Our new icon is meant to encapsulate our evolution and what lays at its heart: our technology, our legacy, and our spirit.

“Evolving is at the core of what do every day,” says our CEO and Co-Founder, Francesco De Stefano. “We continuously strive to undergo technological and organizational evolution to bring Large Format AM to the most advanced industries.”

Our launch wants to highlight a key moment of change, as Caracol has been transforming behind the scenes. Today we announce we’ve moved into a new home, our HQ has moved to Barlassina (MB) that has allowed us to expand our team and technologies, and we are glad to finally present Heron AM to the world.

As our CEO stated, “After our start-up journey working hard to create and grow our market, today we celebrate an amazing milestone. A new home, a new identity, an amazing growing team: all these aspects are embedded in HERON AM, the tangible technological symbol of our evolution.”

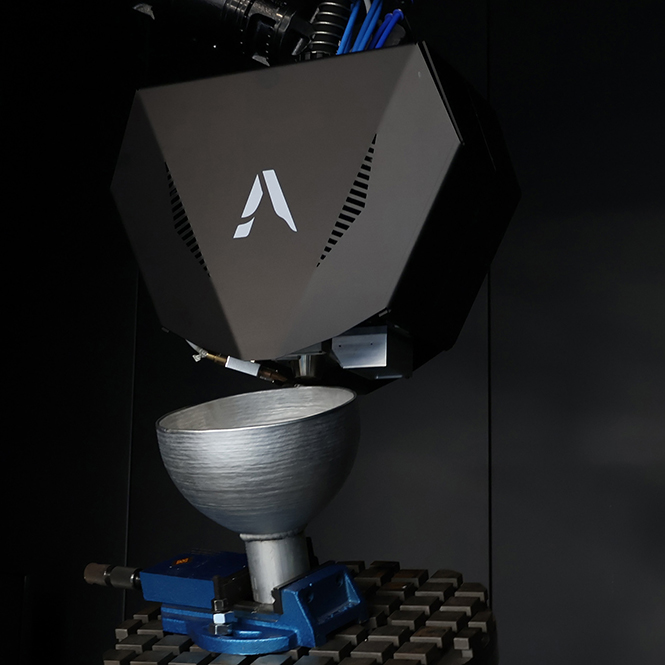

Heron AM is the integrated hardware and software Large-Format Additive Manufacturing platform developed 100% in-house by Caracol.

With this milestone today we are extremely excited to announce Heron AM is now on the market. Caracol will be working with clients to identify applications, opportunities, and manufacture the most complex parts – fundamental to continue pushing LFAM technology forward – as well as provide clients with a solution to internalize the technology in their own production space. This is a fundamental step as it will allow us to delocalize production at the client site, further exploiting one of the benefits of AM and digital manufacturing and help us go towards the goal of distributed global production.

The Evolution of Caracol

Heron AM is comprised of several key elements that have enabled us to guarantee certain quality, accuracy, and performance standards. The platform was developed with an application-first approach: being our system’s first end-user we know what challenges our clients face when working with LFAM technologies. After years of research and development, over 29000 hours of printing, and 150 + projects with clients across industries, we have industrialized a technology that meets the needs of companies working in the most advanced sectors: from Aerospace, to Automotive, Marine, Energy and more.

Our new HQ in Barlassina (MB) is now home to a growing team with over 35 individuals with a set of very diverse backgrounds, skills and capabilities – which we believe is one of the keys to our growing success. It is also home to over 7 Heron AM platforms in their varied configurations – including insulated cells for high-performing polymers or with the 7th axis structure to extend size up to 15-meter parts. Within our space we have a dedicated post-production area, with robotic CNC, as well as a Quality department, with state-of-the-art equipment to inspect and control both the process and all manufactured parts, in accordance with the AS/EN 9100 standard.

As De Stefano mentioned, “We are now ready to launch our international expansion, scaling up to deliver our innovation and the benefits of LFAM across the world. We are extremely excited for what’s ahead.”

At Caracol, we believe evolving is about continuously pushing forward. We will keep moving, transforming, creating. We truly believe our evolution can help guide the future of manufacturing, and that we can be a spark that ignites the revolution.