We designed, engineered, and manufactured a custom satellite tank for our client D-Orbit. The tank serves to contain Nitrous Oxide (N2O) – a gas used as a comburent in rocket engines and internal combustion engines, being non-toxic, stable at room temperature, and relatively easy to store and transport in flight.

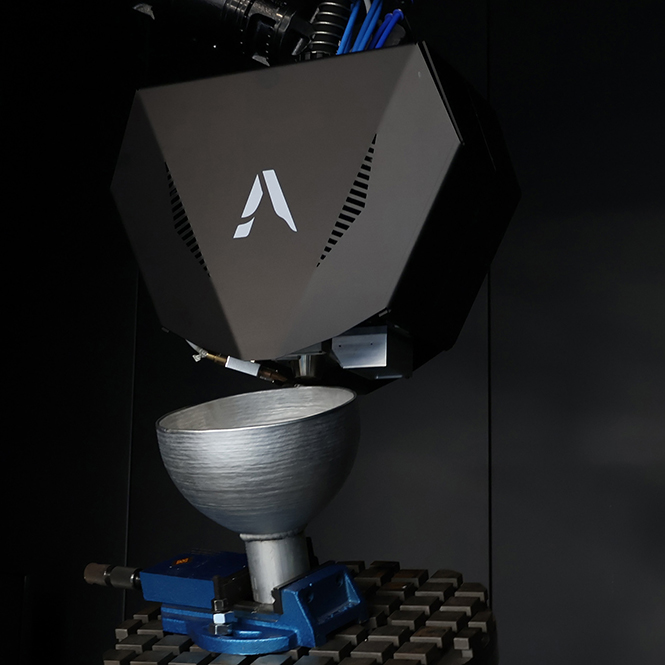

We firstly 3D printed an inner, solid structure using PPS carbon, a performing technopolymer with high mechanical characteristics and chemically compatible with the gas. This structure was hence coated with carbon fibers, to guarantee the seal of the piece.

02 Satellite Tank – D-Orbit

03 Satellite Tank – D-Orbit

The redesigned tank needed to achieve some goals:

- Keep the original performance: the printed component needed to contain a highly pressurized gas at 200/210 bar.

- Weight reduction: the 3D printed tank allowed to replace a previous solution adopted by D-Orbit. To reach the necessary amount of fuel needed for the flight, they supplied their satellite with various smaller tanks made of metal tanks, already present on the market. This custom tank not only already reached the gas capacity needed by the company, but ensured a cut on the weight being printed in plastic.

- Production times: the development of traditional custom tanks has too long development and production times for the needs of satellite launches. This custom design, manufactured through 3D production and hand-laminated carbon fiber drastically reduced the production times by 50% compared to standard production.

- Cost reduction: 3D printing the spindle with PPS CF already gave to the core structure important mechanical and chemical characteristics. This allowed us to substitute the carbon filament winding process previously adopted with a hand-coating carbon fiber, a process which required less carbon and is therefore way less expensive.