Today within the manufacturing supply chains for aerospace applications, the manufacturing of tools, jigs, fixtures, molds, and utensils usually involves milling from solid metal. The produced parts are assembled manually to craft the final pieces, with long production lead times up to around 2-4 months for a single tool on average. Furthermore, due to the significant quantity of material removed from solids and subsequent metal waste, there are high production costs and unsustainable manufacturing processes.

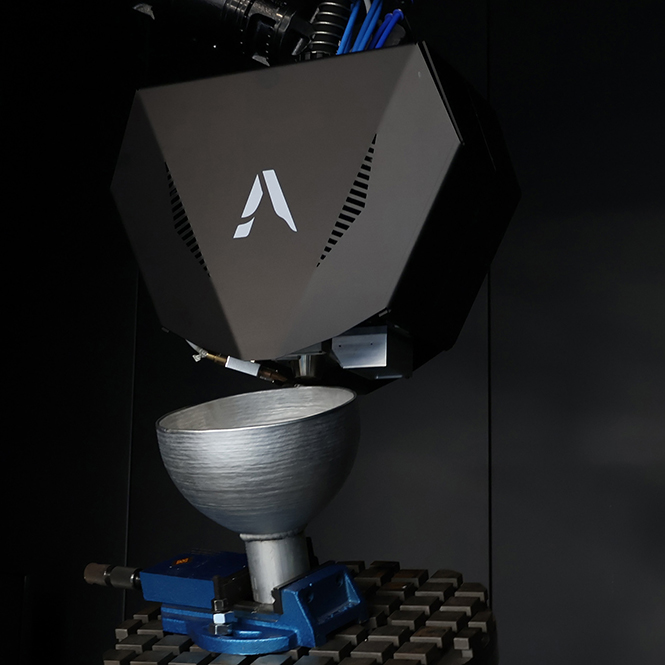

Thus, Caracol began working with big international groups to substitute the traditional processes for large-scale aerospace tooling. One of the key example case studies is this tool for positioning and vacuum gripped drilling of airplane fuselage panels.

02 Aerospace Tooling Jig

03 Aerospace Tooling Jig

The final part manufactured as a single piece with robotic 3d printing, measures about 85cm (w) x 125cm (l) x 33cm (h). This reduced the parts manufactured from over 30 to 1, which meant very little assembly was needed for the final part.

With a digitalized and integrated workflow, the parts are printed in a single piece and finished with CNC milling. This helps achieve the applications’ required dimensional tolerances of 0.1mm and surface roughness of 1.6 μm. The piece was manufactured and ready to use in only 2 weeks, compared to the original 2 months required with traditional processes.

Beyond cutting time, also material waste was cut drastically, and this was supplemented with a significant direct cost advantage of around 30-50% in acquiring the part. As well as advantages in logistics cost as the final part is much lighter in weight and can be stored and handled with greater ease.

This is only the first step towards the development of a more digitalized, efficient, and sustainable aerospace supply chain. It could truly take advantage of benefits like production flexibility, weight, and cost reduction that are possible thanks to this technology.