The benefits of 3D printing for the energy sector

CERTIFICATIONS & SAFETY STANDARDS

Key associations are working to facilitate the certification of parts manufactured with AM, especially thanks to innovation on advanced materials that guarantee safety

ON-SITE PRODUCTION & DIGITAL WAREHOUSING

With plants in remote areas, transport and storage can be costly. 3D print parts right on-site and save all your part file in an always accessible digital library

CUSTOM COMPLEX PARTS

Often components are assembled, bolted, welded, with lengthy lead times. With 3D printing redesign parts as one, produce, and install quickly and cost-efficiently

OBSOLETE PARTS

Thanks to reverse engineering and 3D printing, it is possible to maintain also older equipment and machinery which would otherwise have to be substituted

CUT DOWNTIMES

Equipment breakdowns can result in expansive plant downtimes, and quick production of temporary or permanent parts can ensure business continuity

SUSTAINABILITY

Reduce waste, material used by optimizing geometries, cut impact of logistics, and introduce more efficient production methods

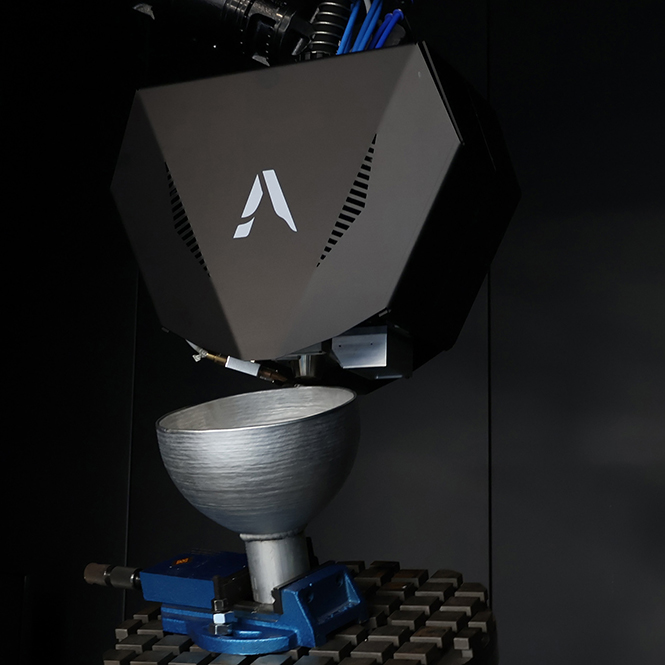

3D Printed Energy Parts

3D printing energy applications

From rapid prototyping, simulacra for testing, temporary parts and tools for maintenance or construction, to custom functional parts, explore how large format additive manufacturing supports the manufacturing for the energy sector.

On-Demand Manufacturing

Caracol Manufacturing Services

Our manufacturing experience is at your service. Bring to life your projects with our teams’ support from design to production – we can deliver finished parts manufactured with the highest quality standards, ensuring your projects are done right.

Discover 3D printing services3D Printing Materials

Advanced materials for industrial 3D printing applications

Caracol LFAM systems can print a wide range of high-performing polymers and composites. Caracol industrial-grade materials are selected, qualified and engineered to provide efficient production in all industries.