Since the day Caracol was conceived, we chose to pursue this technology as a way to bridge the gap for more sustainable production processes!

Environmental sustainability has always been a key pillar for us, we were very excited to work on Regione Lombardia’s tender to incentivize our regions’ innovation for Circular Economy supply chains.

Our project MASAU aimed to develop urban furniture that positively impacted both the environment and society. It was possible thanks to the collaboration of several local players including ComoNExT Innovation Hub, Comune di Lomazzo, Politecnico di Milano, and LCE.

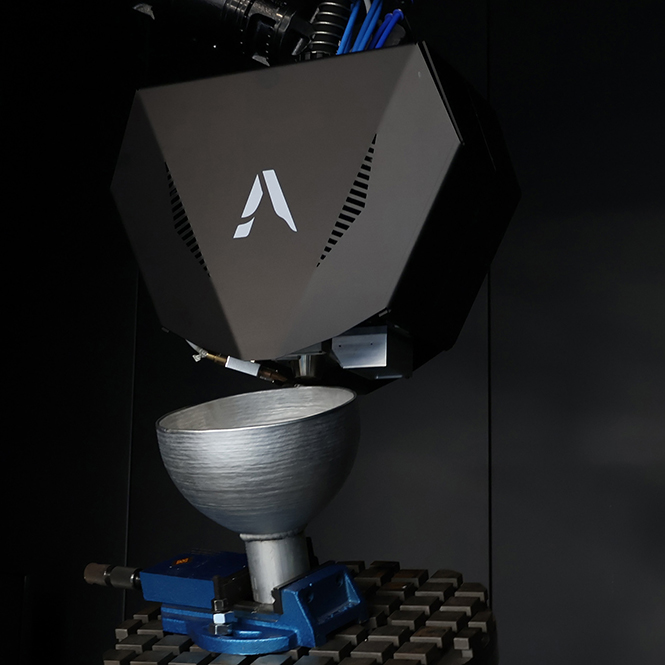

In terms of environmental impact, the project entailed giving new life to recycled polypropylene – choosing a material with a high recycled component as well as be potentially further recyclable, and that could withstand being located outdoors. We optimized the design and through #Heron AM, our #LFAM platform, minimized the impact of the production process in terms of print time, energy consumption, material used, and waste generated.

Another goal was that of creating an environment to foster inclusivity and social interactions within the location identified in the ComoNExT facility. The furniture was designed with organic shapes and set up in a semi-circle, it also included IoT elements to enable smart functions for the installation. For example, the vases allowed to introduce plants that are automatically irrigated with smart sensors recycling bins facilitate waste management, all powered through solar energy.

Caracol working to bridge the gap on sustainable manufacturing

The MASAU project exemplifies the potential of flexibly manufacturing parts with zero-to-positive environmental impact, by producing custom urban elements that were also socially useful.

Thanks to Regione Lombardia’s project, it was possible to analyze the impact of our manufacturing project in an analytical way with an LCA (Life Cycle Assessment) study performed by LCE, which aimed to determine the preliminary impact associated with the full supply chain of these furniture pieces throughout their lifetime, using as a reference the ISO 14040-44 standards.

Several KPIs were studied, including:

- Global Warning Potential (irreversible GWP) (Kg CO2 eq/kg)

- Renewable vs. Non Renewable Energy sources used (MJ/Kg)

- Fresh Water usage (m3/Kg)

- Hazardous & Non-Hazardous waste disposed (Kg/Kg)

- Secondary material (quantity of recycled material recovered) (Kg/Kg)

Through this study, it was possible to see that while 3D printing technologies might still have a considerable environmental impact, there are ways to reduce these technologies’ footprint. At Caracol, many of these actions are implemented daily; such as:

- minimize the use of resources (i.e., materials, energy)

- reduce production time,

- optimize geometries,

- produce parts on-demand,

- eliminate the need for tooling or support material,

- eliminating further assembly or complex post-processing steps where not necessary,

- delocalize production closer to the point of use of parts,

- reduce waste in the supply chain (by using recycled materials or creating zero new waste),

- develop an increasingly efficient technology (Heron AM is more efficient in its energy need in terms of MJ/Kg vs traditional FDM printers)

Caracol is working hard to increase its commitment to positive environmental impact by investing on several innovations for its facilities and on the manufacturing process – including increasing renewable energy sources used, energy efficiency, improved waste management, and much more.