In an industry that is investing heavily in finding ways to improve efficiency and produce increasingly complex and lightweight parts; Caracol together with leading companies in the Energy sector is leveraging LFAM to create piping sections components from thermoplastic composites, reducing lead time, costs, and the overall process sustainability.

The Energy industry is facing numerous challenges in improving its value chain. When it comes to manufacturing piping components it faces limitations related to complex geometries, stringent requirements for resistance to chemicals and environmental conditions, and operational costs. Traditionally, producing pipes requires tooling, metals, and lengthy production times, furthermore, maintaining metallic piping for water and chemicals results in high maintenance costs, leading to a high economic and environmental impact. The increasing demand for reducing manufacturing’s carbon footprint and production efficiency is driving the industry towards alternative technologies. In this context LFAM stands as a more flexible and sustainable solution for complex pipe sections and junctures.

Caracol LFAM technology in piping manufacturing

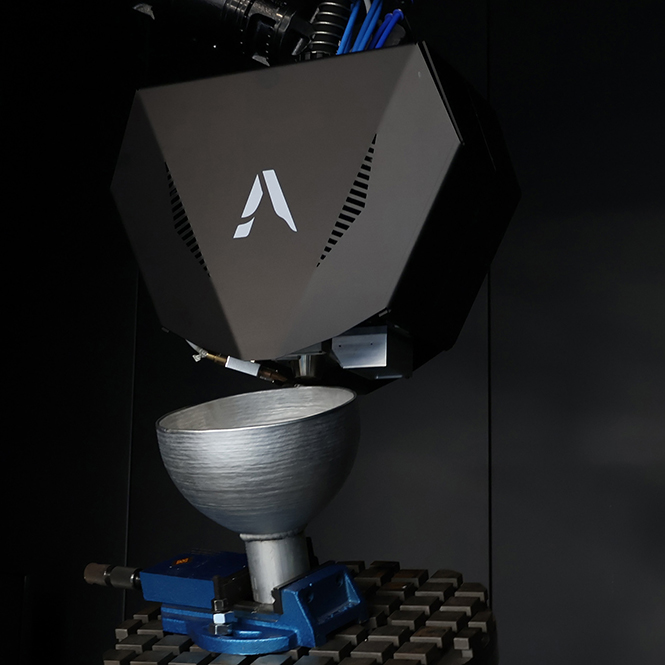

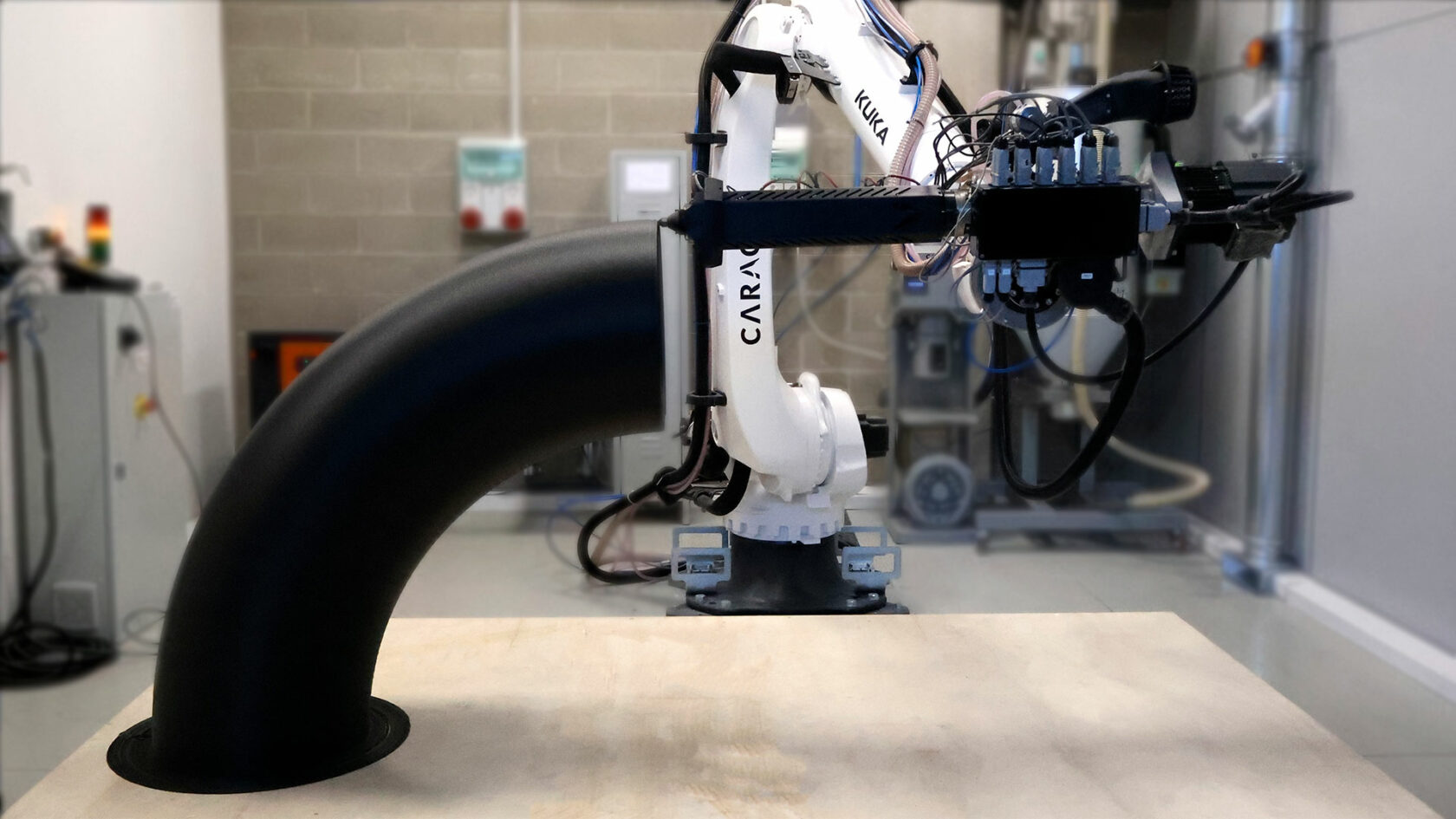

Thanks to Heron AM platform, Caracol has managed to develop a cutting-edge process that utilizes non-metallic materials for pipe production, pivoting towards a more efficient and cost effective manufacturing process. Specifically, leveraging a robotic large format platform like Heron AM it was possible to create different functional piping sections and components – such as curves, connectors, and x-way joints. In fact, in addition to being a low- impact process, 3D printing is also particularly advantageous for applications with complex geometries in limited production volumes. Three types of geometries, that faced difficulties with traditional technologies, were targeted for a production, testing, and validation: curved sections – leveraging multiplanar printing, connectors – printing varying pipe thicknesses, and x-way joints – with internal sections and canals. Specifically, a thorough study was done for multiplanar printing of curved pipe sections. Working with robotic LFAM means leveraging the 6+ axis of the robotic kinematics to increase the degrees of freedom when working on the part’s slicing. One of the features this enables is multiplanar slicing, which means that the extruder is programmed to adjust its orientation, remaining perpendicular to the printed section by varying the angle of print throughout the full job. Determining the exact parameters and validate the application meant studying several parameters, such as:

- curvature radius (R) – the angle formed between midlines of two successive layers

- base circumference diameter (Dbase)

- time (t) – determining the toolpath length

- layer time (t layer)

- layer height (h layer)

- material and temperature (°C) – to understand best printing settings for ideal adhesion between layers, considering material choice, thermal properties, and the above-mentioned parameters

Furthermore, Caracol worked to test materials commonly used and already qualified for use in the Energy industry, such as HDPE (high-density polyethylene – natural or with glass fiber), as well as rPP GF (recycled polypropylene with glass fiber) for certain applications. A key question was to understand the benefits and risks of using non-metallic materials for chemical processing, water treatment, oil and gas, and power generation as a way for the industry to overcome limits of metals. While more work has still to be conducted to fully qualify and certify the use of these materials, the study allowed to assess several benefits, including:

- corrosion resistance

- weight reduction

- durability

- cost efficiencies throughout the parts’ lifecycle

- chemical compatibility

- environmental and safety benefits in operations and maintenance

Project outcomes and benefits

What was evaluated through these projects was that the production process of piping components through LFAM with thermoplastic composite materials, offers several advantages over traditional methods, including:

- Reduced lead times: achieved through quick production, elimination of tooling and cutting several steps in the process, can lead to faster production times by up to 50%

- Minimized material used and waste: 3D printing allows for the use of only the necessary material, saving up to 20% of the raw material used, and reducing waste by up to 20% on some of these parts

- Greater design freedom: engineers can develop components with greater geometric complexity that are optimized for their functionality

- Simpler value chain – eliminating tooling, molds, and supports, cutting steps in production, eliminating manual assembly operations, and by printing near net-shape parts that only require simple post-processing operations in the interface sections

- Environmental sustainability: Caracol’s process can incorporate recycled materials, contributing to a reduced overall environmental impact

Furthermore, AM process also enable to introduce additional benefits, such as logistics and process efficiencies. Once parts are validated and qualified, thanks to a digital inventory it is possible to print parts on-demand, on-site, without the need to hold storage for parts or lengthy plant downtimes to substitute spare parts.

Ultimately, LFAM is proving to be an innovative and sustainable solution to address the manufacturing challenges of the energy sector. Next steps will enable to undergo full testing at the clients’ sites, to gather data and fully certify the use of 3D printed piping sections in energy plants. Nonetheless, thanks to these successful case studies, Caracol highlighted how large format 3D printing not only can effectively produce precise parts with complex geometries, bypassing traditional technologies’ limitations and reduce costs, but also it also unlocks new possibilities in the production of small series of parts, in terms of overall production efficiency, as well as implementing a more sustainable manufacturing approach.