A custom car project highlights how large 3D printed mock-ups can accelerate product development in the automotive industry, from concept design to fitting and production.

Why mock-ups are key to car development: visualizing, adjusting, and reimagining vehicles before they hit the production line

Mock-ups are scale or full-size models of a design, used for various purposes, such as aesthetic design evaluation, fit-testing, product testing, demonstration, teaching, and promotion. In the Automotive industry, these physical models of car designs range from simple sketches to full-scale prototypes. Made of various materials, such as clay, foam, plastic, or metal, they are essential for validating the functionality, aesthetics, and performance of new car concepts before they go into production.

Mock-ups are especially important for custom-made car components because they can help to:

- Validate the precise fit of the part to the custom-design car, before it goes into production;

- Reduce the risk of errors, defects, and rework, saving time and money;

- Enhance the design flexibility and innovation, allowing for more complex and unique geometries and functions;

- Optimize the inventory and supply chain management, by reducing the need for storage and transportation of large and heavy parts;

- Satisfy the customer’s needs and preferences, by offering more personalization and customization options.

The impact of 3D printing on Mock-ups and Full-scale Prototypes in the Automotive Industry

Large format additive manufacturing (LFAM) is an innovative technology that enables the creation of large parts or structures by depositing layers of material, such as plastic, metal, or composite, using a print head controlled by slicing and automation software.

As traditional methods of making mock-ups can be costly, time-consuming, and wasteful, LFAM systems are increasingly adopted in this specific application. Through the use of large-scale 3D printers, the production and supply chain of automotive mock-ups can benefit from several advantages, such as:

- Faster and more efficient manufacturing, as LFAM systems can print large parts in one piece, without the need for molds, tools, or assembly;

- Reduced material waste and cost, especially by using granulate-based printing, which is cheaper and more sustainable than filament-based methods;

- Improved quality and accuracy, as LFAM users can produce complex geometries and fine details that are difficult or impossible to achieve with traditional methods;

- Enhanced design freedom and innovation, as this technology enables the exploration of new shapes, forms, and functions that are not constrained by conventional manufacturing limitations.

Depending on the purpose and complexity of the design, Large Format Additive Manufacturing systems can be used for mock-ups in various stages of the production process:

- For conceptual design by quickly creating rough mock-ups of new ideas, to test the feasibility, functionality, and aesthetics of the design;

- For detailed design by helping to refine the mock-ups with more details, accuracy, and realism, to evaluate the performance, durability, and ergonomics of the design;

- For presentation and marketing producing realistic and attractive mock-ups of the final design, to showcase the features, benefits, and value of the product to potential customers, investors, and partners.

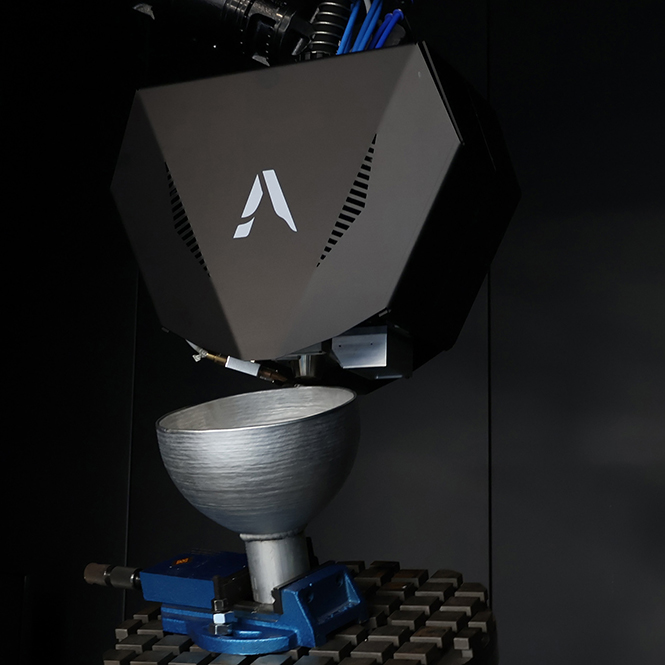

Caracol and Titans of CNC collaborate on the front grille 3D printed mock-up and end-use custom part for a 1968 Chevrolet C10 custom build by Gas Monkey Garage, Dallas Texas.

Titans of CNC is a US-based company providing tools and equipment to CNC manufacturers. Their experienced CNC technicians and engineers have supported Gas Monkey Garage’s team in designing a custom car’s front grille. Caracol joined the project by 3D printing the carbon fiber-reinforced ABS, 1:1 mock-up for design validation and fit testing, to ensure the most precise and effective production of the final aluminum component. As a result, the manufacturing process achieved a better fit quality and cost efficiency in a shorter lead time, if compared to traditional methods.

Replacing traditional manufacturing methods such as metal milling required first optimizing and redesigning the geometry with a Design for Additive Manufacturing (DfAM) approach, provided by Caracol’s team to fine-tune the engineered part with a 3D model that enabled to maximize all the benefits of additive manufacturing. Using the company’s patented Eidos Manufacturing Software, the 3D printing slicing path & parameters were also optimized to guarantee the most detailed and precise production of the one-part mock-up. A high level of detail and realism was achieved without structural post-processing interventions, which only involved sanding and painting of the part. The fit check enabled to detect small design refinements that were needed on the design of the finished part, avoiding errors and potential waste that would’ve emerged from an incorrect design.

The 1900 x 300 x 500 mm front grille mock-up was manufactured in a single piece with a Heron AM 300, using the High Accuracy printing head. The production cycle lasted 10 hours and led to 70% decrease in time production and 60% cost savings, compared to traditional manufacturing methods.