Industry: Architecture & Construction,

Material: rPP GF,

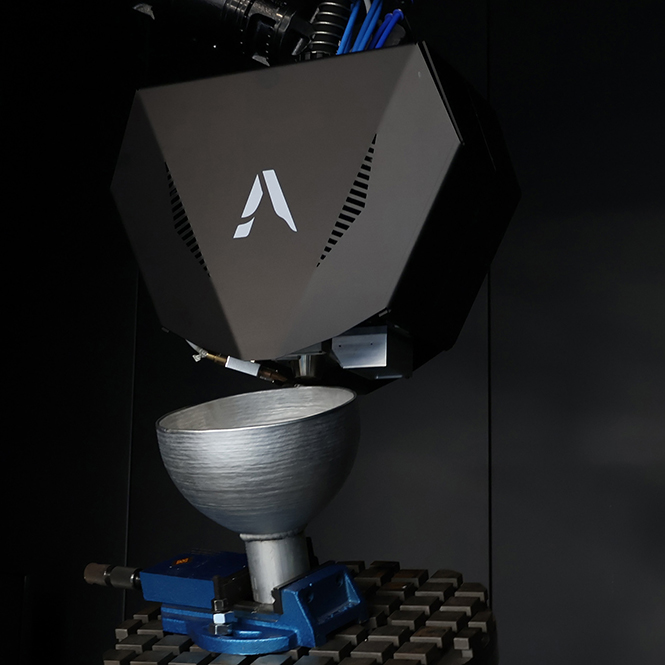

Technology: LFAM,

Client: Yamamay

Industry: Architecture & Construction,

Material: rPP GF,

Technology: LFAM,

Client: Yamamay

From Yamamay‘s creative idea, we brought to life their iconic “Y” with a 3D printed, four-meter-tall sculpture, that will become the company’s landmark in their HQ in Gallarate (VA).

The sculpture is built in two key elements we manufactured with our LFAM systems: a 1-meter tall cement plinth basement made from a custom 3D printed formwork, and a 3-meter Y logo made from recycled polypropylene, which was varnished with a protective layer to ensure resistance to weathering.

Beyond the size and innovativeness, what really stands out is the fact that this project was possible thanks to the synergic collaboration between a far-sighted company that is pushing daily to pursue its objectives in circular economy and a company that ideated a revolutionary technology that enables sustainable industrial production.

02 Yamamay Totem

03 Yamamay Totem

LFAM FOR THE AUTOMOTIVE INDUSTRY

Related Case Studies

Check out our success stories

-

Case studies. Sangiorgio Marine redefines yacht superstructures production with LFAM

-

Case studies. Applying robotic LFAM in the production of Pershing GTX116 aerodynamic grilles

-

Case studies. Duqueine Automotive Set New Standards in Racing Car Development

-

Case studies. The first functional monolithic catamaran additively produced with V2 Group

-

Case studies. Gosper lamp: leveraging robotic LFAM technology to create stunning lighting design

-

Case studies. Stacked modules: 3D printing meets craftsmanship to redefine furniture production

-

Case studies. Alstom redefines the production of simulator driver desks with LFAM

-

Case studies. 3D-printed 1:5 nose mock-up for Alstom

-

Case studies. Shaping the manufacturing of industrial tooling with large format 3D printing

-

Case studies. Custom Conveyor Screw for Industrial Machinery

-

Case studies. Multi-Material Neck Flange for the Oil & Gas Industry

-

Case studies. Vipra AM in Marine Propeller Manufacturing

-

Case studies. High-Precision Autoclave Cure Tools for Aerospace

-

Case studies. 3D printing piping for the energy industry

-

Case studies. The first 3D printed ISO certified marine gangway

-

Case studies. Robotic 3D printing of custom design furniture

-

Case studies. Van Venrooy and Caracol 3D print end-parts for automotive custom vehicles

-

Case studies. Bringing LFAM to industrial production for advanced applications in the automotive sector

-

Case studies. LFAM aerospace composite parts fly high with 3D printed autoclave molds

-

Case studies. How large 3D printed mock-ups can accelerate the automotive industry

-

Case studies. 3D printed tools for aircraft manufacturing

-

Case studies. Caracol working to bridge the gap on sustainable manufacturing

-

Case studies. Pressurized Tanks for Space with WAAM

-

Case studies. 3D printed autoclave cure tooling for the automotive industry

-

Case studies. Yacht Superstructures – Air Grids

-

Case studies. Wind Blades’ Lamination Tooling

-

Case studies. Beluga – 3D Sail Boat

-

Case studies. Torre Capitolare

-

Case studies. Valentino Rossi gets giant 3D printed helmet from Caracol AM

-

Case studies. Satellite Tank – D-Orbit

-

Case studies. Aerospace Tooling Jig

-

Case studies. Caracol at Isola Digital District 2020

-

Case studies. Upcycling – Maire Tecnimont

-

Case studies. 3D Bar

-

Case studies. Race Car Spoiler