ph. Cover – Capitolare Tower

The advent of 3D printed furniture is transforming how the industry looks at creating furnishing pieces, bringing innovative designs, cost-efficiencies, and sustainability to the center of every project

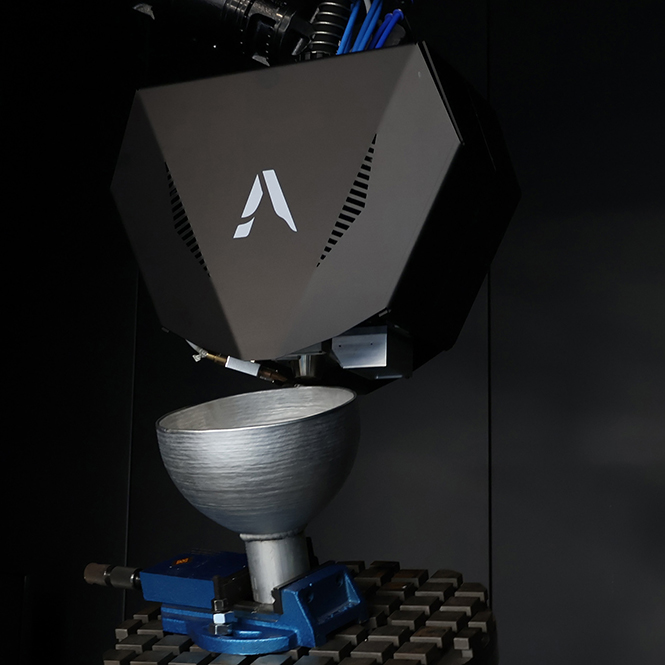

By incorporating large-format additive manufacturing (LFAM) technologies, such as Caracol’s Heron AM, the production of unique, high-quality furniture is now achievable and scalable into line production of design pieces. This process is reshaping traditional manufacturing models, reducing the overall environmental footprint of production, optimizing costs and lead time for projects, and transforming the choice of materials used.

From concept to reality

The creation of 3D printed furniture starts with a digital design. Designers use CAD software to create 3D models that allow them to experiment with form, function, and style. This approach is a hallmark of 3D printing furniture design, where complex shapes and organic structures can be easily accomplished.

Robotic LFAM technology allows to leverage the flexibility of its axes to introduce new slicing approaches, such as multiplanar, conformal, and non-planar 3D printing to maximize the freedom in design. Technologies such as Heron AM, together with a partner that can help master production from slicing to material processing, enable the creation of highly accurate printing of large parts, such as tables, chairs, couches and more. This flexibility ensures the adaptability needed to develop 3D printed furniture pieces that are both functional and artistic, as well as structurally sound and visually appealing.

Benefits of 3D printing in furniture manufacturing

3D printing furniture design is revolutionizing supply chains in the industry by merging efficiency, sustainability, and overall process flexibility. LFAM empowers designers to use advanced techniques like parametric or generative design, which optimizes material use, weight and structural strength to tackle challenges and reduce costs. This process enables the creation of intricate geometries and unique finishes, such as organic-like surfaces.

Key benefits include:

- Wide application range: from 3d printed outdoor furniture such as urban public or private gardens, pieces tailored to unique spaces architectural projects

- Cost-effectiveness: no need to produce costly prototypes, molds or tooling, reducing upfront production costs and lead time

- Material efficiency: layer-by-layer deposition process ensures that only the required material is used for production, eliminating waste typically associated with post-processing

- Customization: bespoke designs tailored to specific client needs, from ergonomic office chairs, unique residential furniture or bold artistic installations

- Design freedom: generative design allows to create intricate geometries, organic shapes and optimized structures

- Broad choice of sustainable materials: possibility to introduce several bio-based or recycled material options, including materials with natural fiber (for example, materials that mimic 3D printing wood furniture).

Why 3D printing enables more sustainable production

Large-format additive manufacturing is redefining sustainability in 3D printed furniture production by integrating eco-friendly principles and advanced technology. Caracol’s Heron AM system exemplifies this by utilizing pellet-based materials, leveraging bio-based or recycled plastic options, that is easy to recycle and that enables the activation of virtuous circular economy cycles. Achieving improved sustainability is possible through:

- Design optimization: efficient use of materials without tool, molds or supports

- Energy efficiency: streamlined processes minimize energy consumption

- Local production: reduces logistics-related environmental impact

- On-demand production: production only when needed, avoiding costs and environmental impact of storage

- Lifecycle design: promotes recycling and circular material use

Complementing this, Caracol and its global network of partners provide support on material characterization, design consultancy, and training, empowering clients to maximize LFAM’s potential. With a focus on sustainability, Caracol integrates circular economy principles into every production step.

The future of 3d printed furniture

3D printing is more than just a tool for creating furniture, it’s a paradigm shift that redefines how furniture is designed, produced and used. Companies like Caracol are leading the way by innovating 3D printed furniture while also advancing sustainable practices. With 3D printing furniture design driving this transformation, the future of the furniture industry is being reshaped, one layer at a time.

To know more about 3D printing applications for the creative industry: read our White Paper!