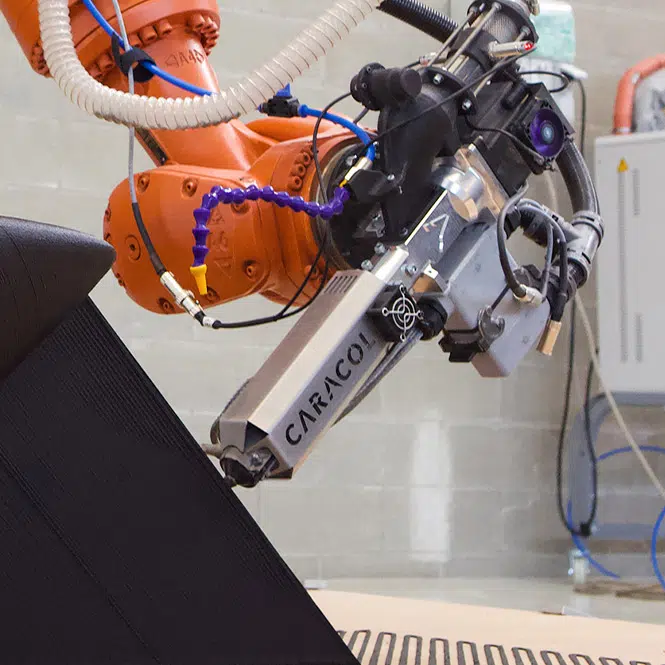

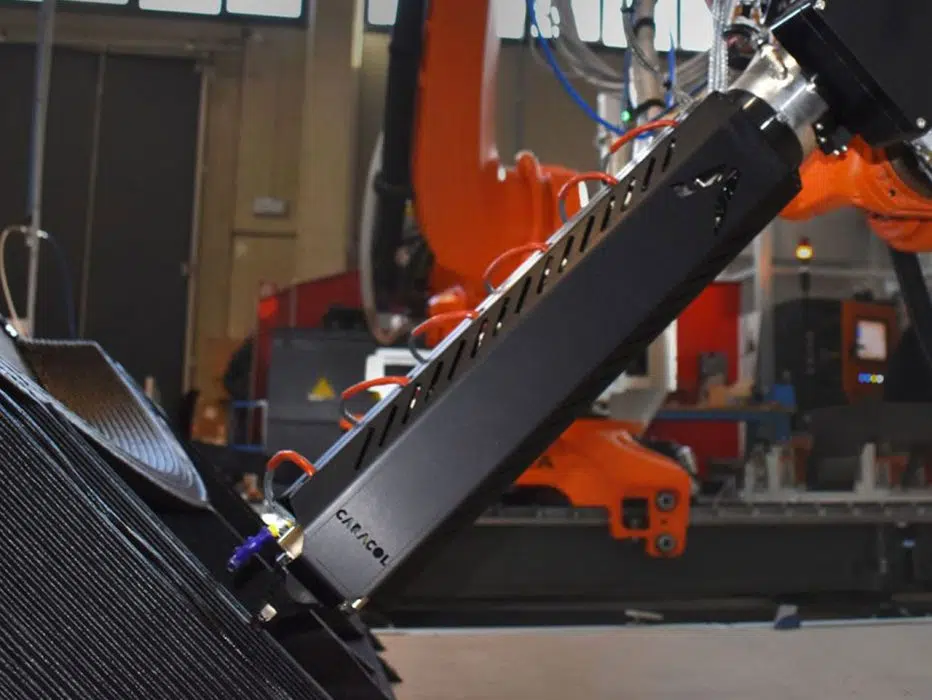

Additive Manufacturing Technologies

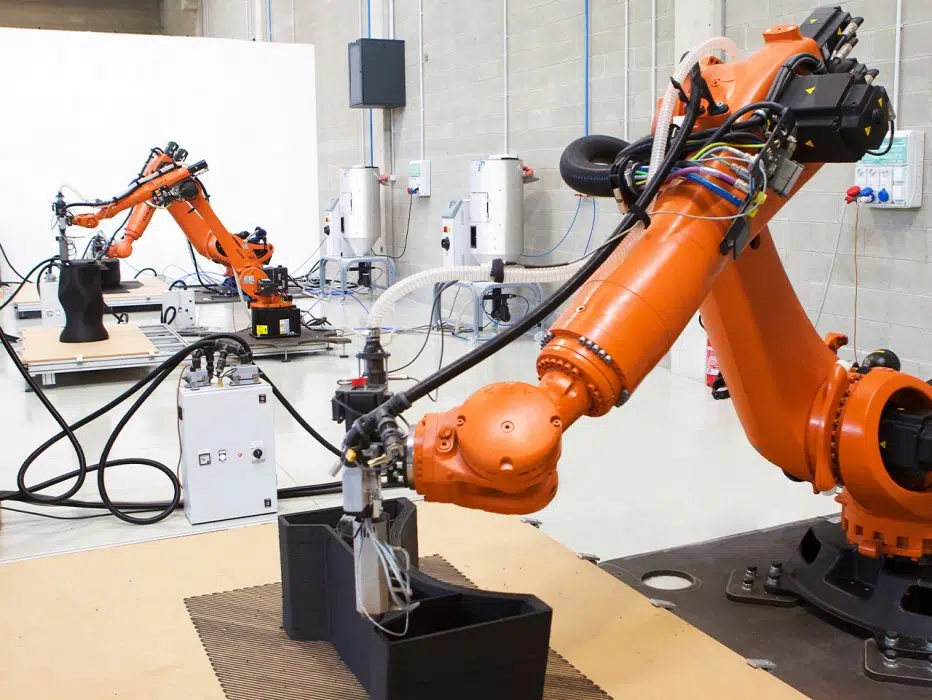

Large Format 3D Printers

Are you looking to bring the benefits of 3D printing to your large-scale industrial parts production? Look no further. Learn more on about our LFAM technologies, find your best fit.

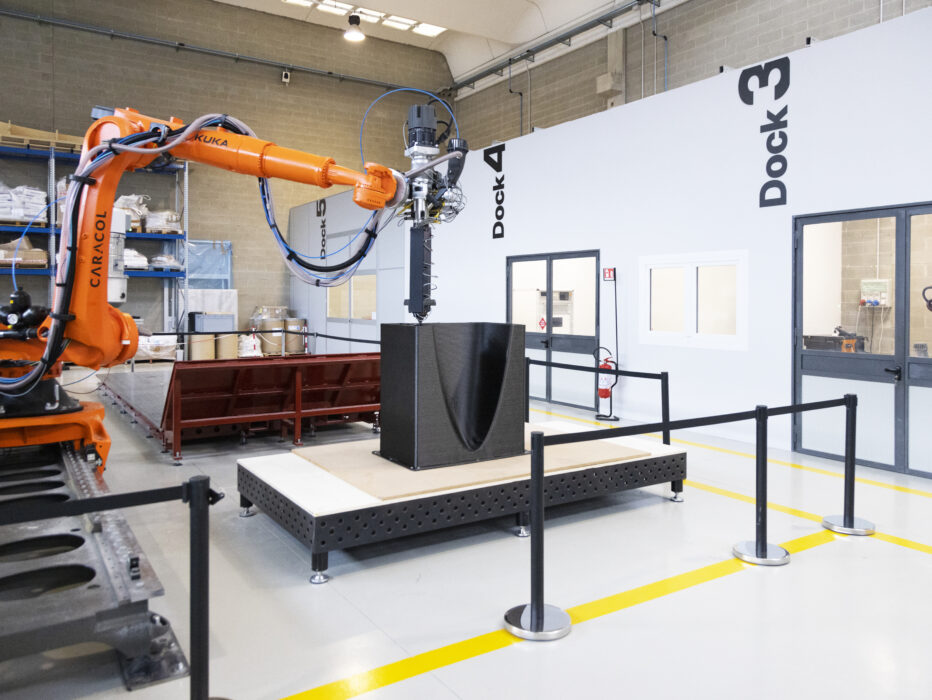

Caracol Manufacturing Services

On-Demand Manufacturing

Get to know our LFAM technologies by 3D printing your parts with us. Access best in class large format capabilities from part design to production, post-processing and inspection. We deliver innovation to your projects, ensuring the most demanding industrial quality standards.

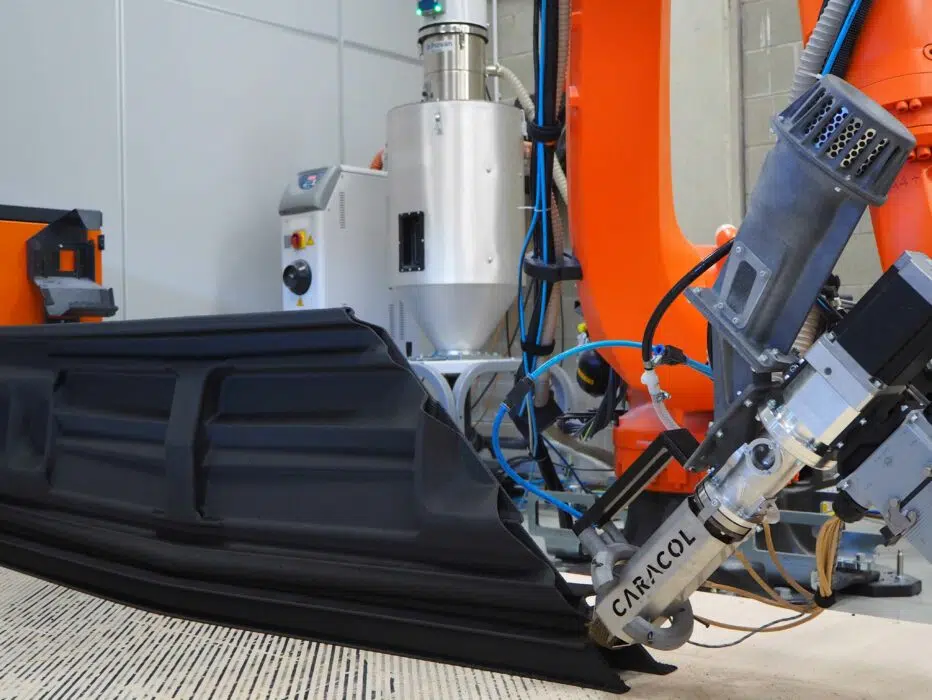

Caracol AM Network

Near customer, everywhere

With our global offices and network of best-in-class partners, we can assist you with any of your 3D printing needs whenever and wherever you are.

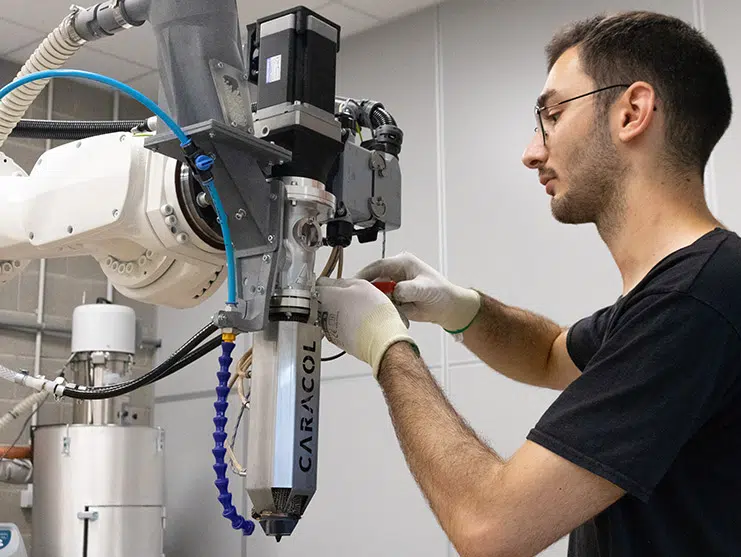

Caracol Support

Customer support hub

Caracol’s experts are ready to assist for you to make the most out of your Additive Manufacturing technology.

Discover Caracol Support